Understanding the Critical Role of Specialized Gear

The realm of military operations demands unparalleled reliability, precision, and durability from every piece of equipment. Beyond the primary weapons and platforms, there exists a vast and intricate ecosystem of accessories that are fundamental to mission success, soldier safety, and operational effectiveness. These components, often overlooked, form the backbone of modern military logistics and individual kit customization. This article delves deep into several key categories of these essential items, exploring their specifications, applications, and the critical factors involved in their selection and use. We will explore essential but often underexplored niches, including high-temperature resistant military hose fittings, tactical helmet accessory mounting solutions, military-grade anti-corrosion lubricants, ballistic eyewear replacement lenses, and ruggedized communication device protective cases.

High-Temperature Resistant Military Hose Fittings

In the extreme environments where military vehicles and aircraft operate, standard hydraulic and pneumatic systems would fail catastrophically. The transfer of fuels, oils, and hydraulic fluids under high pressure and intense heat requires fittings that can withstand immense stress.

Materials and Manufacturing Standards

The construction of these fittings is governed by stringent military specifications (MIL-SPEC). Common materials include:

- Stainless Steel (CRES): Particularly types 316 and 321, known for their excellent corrosion resistance and strength at elevated temperatures.

- Inconel: A nickel-chromium-based superalloy used in the most extreme temperature applications, such as jet engines and exhaust systems.

- Titanium: Offers an exceptional strength-to-weight ratio and good resistance to corrosion and heat.

These materials are often subjected to specialized processes like passivation to enhance corrosion resistance and annealing to relieve stresses induced during machining.

Key Performance Metrics and Testing

Every batch of high-temperature resistant military hose fittings must pass a series of rigorous tests to ensure they meet the required performance benchmarks. These tests are designed to simulate the harshest possible conditions they might encounter in the field.

- Pressure Testing: Fittings are subjected to pressures significantly higher than their rated working pressure to check for leaks, deformation, or burst failure.

- Temperature Cycling: Components are repeatedly cycled between extreme high and low temperatures to test for thermal fatigue, cracking, or seal degradation.

- Vibration and Shock Testing: Simulating the environment aboard a moving vehicle or aircraft, this test ensures the fitting will not loosen or fail under constant vibration or sudden impact.

- Salt Spray Testing: A prolonged exposure to a salt fog atmosphere evaluates the fitting's resistance to corrosion, a critical factor for naval applications.

Comparison of Common Fitting Types

Selecting the right type of fitting is paramount. The choice depends on the fluid type, pressure, temperature, and required frequency of disconnection. Below is a comparison of several common types used in military applications.

JIC (Joint Industry Council) fittings are known for their 37-degree flare seating surface, providing a strong, leak-free connection suitable for high-pressure hydraulic systems. In contrast, ORFS (O-Ring Face Seal) fittings utilize a flat face with an O-ring, offering a superior seal that is highly resistant to vibration and thermal cycling. NPT (National Pipe Tapered) threads are common but rely on thread deformation for sealing, which can be less reliable under extreme thermal cycling compared to metal-to-metal or O-ring seals.

| Fitting Type |

Primary Seal Mechanism |

Max Temp Rating (Approx.) |

Best For |

Limitations |

| JIC 37° |

Metal-to-metal flare |

400°F (204°C) |

High-pressure hydraulics |

Can be over-torqued, leading to cracking |

| ORFS |

Elastomeric O-ring |

300°F (149°C)* |

Systems with high vibration |

O-ring material limits temperature |

| NPT |

Tapered thread interference |

500°F (260°C) |

General fluid & gas conveyance |

Prone to leakage if not properly sealed with compound |

| MS (Military Standard) |

Varies (often metal-to-metal) |

450°F+ (232°C+) |

Aerospace and specific vehicle systems |

Very specific application, can be costly |

Highly dependent on the specific O-ring polymer used (e.g., Fluorocarbon vs. Perfluoroelastomer).

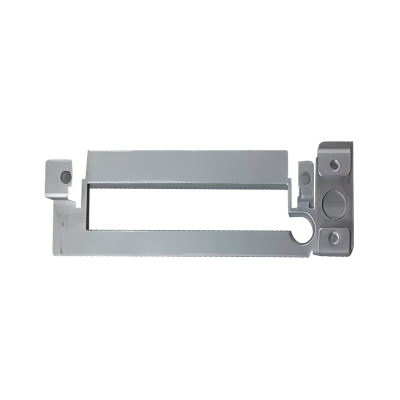

Tactical Helmet Accessory Mounting Solutions

The modern combat helmet has evolved from a simple piece of protective equipment into a sophisticated platform for integrating critical technology. The system that allows for this integration—the mounting solution—is as important as the accessories themselves. A secure, stable, and versatile mount is essential for ensuring night vision devices, communication headsets, cameras, and lights perform reliably when needed.

Evolution of Mounting Standards: From Rails to Adapters

The industry has largely consolidated around a few key standards. The most prevalent is the Picatinny rail (MIL-STD-1913), a robust bracket with multiple slots for attaching accessories. However, helmet-specific systems have been developed to address the unique needs of head-borne equipment.

- NVG Shrouds: The standardized bayonet-style mount (e.g., USGI or NATO standard) that serves as the fixed base for attaching night vision goggle brackets. It must be incredibly strong to handle the weight and leverage of the goggles.

- Helmet Rails: Miniature Picatinny or proprietary rails (like the MICH/ACH system) can be attached to the helmet's sides or front, allowing for the attachment of lights, laser aiming devices, or cameras.

- Universal Adapter Plates: Solutions that allow users to attach equipment designed for one helmet system (e.g., Ops-Core) to another (e.g., Team Wendy), increasing interoperability.

These tactical helmet accessory mounting solutions must be made from materials like high-strength polymers or machined aluminum to provide a perfect balance of low weight and high durability.

Considerations for Selecting a Mounting System

Choosing the right mount is not a one-size-fits-all process. Several critical factors must be considered to ensure optimal performance and safety.

- Weight Distribution: A heavy accessory mounted high on the helmet can cause neck strain and affect balance. Mounts should allow for positioning that keeps the helmet's center of gravity as low as possible.

- Retention Security: The mount must have a positive locking mechanism that prevents the accessory from accidentally detaching during dynamic movement, airborne operations, or if the wearer is jolted.

- Helmet Shell Compatibility: Not all mounts are compatible with all helmets. The curvature, thickness, and existing hole patterns of the helmet shell must be matched with the mount's design.

- Quick-Detach Capability: In certain situations, the user may need to rapidly jettison an accessory. A good mounting system offers a secure lock while also allowing for intentional, quick removal when necessary.

Military-Grade Anti-Corrosion Lubricants

Corrosion is a constant and insidious enemy of military equipment. It can seize moving parts, degrade structural integrity, and cause electrical failures. In harsh environments—from salty sea air to sandy deserts and humid jungles—the protective qualities of lubricants are as important as their ability to reduce friction. Military-grade anti-corrosion lubricants are formulated to provide a robust, long-lasting barrier against moisture and contaminants while ensuring smooth operation of weapons, vehicles, and other machinery.

Formulation and Key Properties

These are not simple oils; they are complex chemical formulations designed to meet specific MIL-SPEC requirements like MIL-PRF-63460 or MIL-PRF-81322. Their efficacy stems from a combination of base oils and advanced additives.

- Base Oils: Typically synthetic (e.g., polyalphaolefin - PAO) for superior performance across a wide temperature range (-60°F to 500°F) and improved longevity compared to mineral oils.

- Corrosion Inhibitors: These are the most critical additives. They form a protective molecular layer on metal surfaces, preventing oxygen and water from initiating the electrochemical reaction that causes rust.

- Anti-Wear Additives: Compounds like Zinc Dialkyl Dithiophosphate (ZDDP) create a sacrificial layer on metal parts, preventing scuffing and wear under high load.

- Water Displacement: A key property of many military lubricants (e.g., the famous CLP - Cleaner, Lubricant, Protectant) is the ability to penetrate between a water film and the metal surface, displacing the water and providing protection.

Application-Specific Use Cases

The choice of lubricant depends heavily on the application. Using the wrong type can be ineffective or even damaging.

- Small Arms: Requires a lubricant that functions reliably in extreme cold and heat, doesn't attract dust and sand (a property known as "dry lubrication"), and protects the bore from corrosion. It must also be safe for the weapon's materials and not degrade over time.

- Vehicle and Aircraft Mechanisms: Hinges, latches, cables, and gears need lubricants that can handle high loads, resist washout from rain or immersion, and prevent corrosion in often exposed conditions.

- Electronics and Electrical Connectors: Specialized dielectric lubricants and corrosion preventatives are used on electrical connectors to prevent current leakage and protect against corrosion caused by moisture, without interfering with the electrical signal.

- Marine Environments: Equipment exposed to saltwater demands the most robust anti-corrosion formulations, often with thicker consistencies or grease-like properties to provide a long-lasting barrier.

Ballistic Eyewear Replacement Lenses

Ballistic eyewear is a mandatory piece of personal protective equipment, designed to shield the eyes from fragmentation, projectiles, and other battlefield hazards. However, the lenses themselves are consumable items—they can become scratched, fogged, or damaged, impairing vision and compromising protection. Having a supply of genuine, high-quality ballistic eyewear replacement lenses is crucial for maintaining operational readiness and individual safety.

Lens Material Technology: Beyond Basic Polycarbonate

While all ballistic lenses start with a polycarbonate base due to its inherent impact resistance, the treatments applied to them are what define their performance.

- Anti-Scratch Coating: A hard, clear coating applied to the outer surface to resist abrasion from dust, sand, and cleaning. The quality of this coating varies greatly and is a key differentiator.

- Anti-Fog Coating: A hydrophilic coating that causes moisture to sheet evenly across the lens instead of forming discrete droplets that obscure vision. This is often applied to the inner surface.

- UV Protection: Inherent in polycarbonate, but often enhanced to provide 100% protection against UVA and UVB rays.

- Mirrored and IR Protection: Some specialized lenses have a mirrored finish to reduce glare or are coated to attenuate infrared light, offering a tactical advantage when using night vision devices.

Ensuring Compatibility and Authenticity

Not all replacement lenses are created equal. Using counterfeit or out-of-spec lenses can be dangerously ineffective.

- ANSI/ISEA Z87.1 Certification: Lenses must meet this U.S. standard for impact resistance. For military use, they should also meet the more stringent MIL-PRF-31013 standard.

- Frame-Specific Design: Lenses are precision-cut to fit specific frame models. A lens designed for one brand will not necessarily fit or seal correctly in another, potentially leaving gaps that allow debris to penetrate.

- Optical Clarity:

Substandard lenses can have optical distortions that cause eye strain and headaches during prolonged use. Genuine replacement lenses are manufactured to ensure perfect optical clarity, free from waves or distortions that can impair a soldier's ability to aim or identify threats accurately. This is a critical factor that separates certified mil-spec lenses from commercial imitations.

Ruggedized Communication Device Protective Cases

Modern military operations are driven by communication. Radios, satellite communicators, and ruggedized tablets are essential for coordination and data sharing. These devices are expensive and highly sensitive. Ruggedized communication device protective cases are designed to shield this vital equipment from the brutal shocks, vibrations, dust, water, and extreme temperatures encountered in the field, ensuring they remain functional when it matters most.

Design Philosophy and Protective Features

The design of these cases goes far beyond a simple plastic box. They are engineered systems based on military standards like MIL-STD-810 for environmental engineering and MIL-STD-461 for electromagnetic interference.

- Impact Resistance: Constructed from materials like polycarbonate, ABS, or structural foam, the outer shell is designed to absorb and dissipate energy from drops and impacts. Internal cushioning, often custom-molded foam, cradles the device, preventing it from moving and absorbing shock.

- Environmental Sealing: A critical feature is the ingress protection (IP) rating, typically IP67 or higher. This denotes complete protection from dust (6) and protection from immersion in water between 15cm and 1m for 30 minutes (7). This is achieved through gaskets, O-rings, and sealed port covers.

- Operational Accessibility: The case must allow the user to operate the device without removing it. This is done through transparent touch-screen compatible membranes, sealed pass-throughs for cables and antennas, and tactile buttons that activate the device's controls through the case material.

- EMI Shielding: Some cases incorporate metallic meshes or coatings to protect the sensitive electronics inside from external electromagnetic interference that could disrupt functionality.

Selecting the Right Case for the Mission Profile

The optimal case depends on the device and the operational environment. A case for a handheld radio used by dismounted infantry has different requirements than one for a vehicle-mounted tablet.

- Size and Weight: For personnel carrying the case, minimizing bulk and weight is a priority without sacrificing critical protection.

- Mounting Options: Cases often feature built-in rails, Molle attachment systems, or vehicle dock compatibility to secure the device to a vest, vehicle, or workstation.

- Thermal Management: In extreme heat, a sealed case can trap heat from the device itself, leading to overheating. Some advanced cases incorporate passive cooling vents or even active cooling systems while maintaining environmental seals.

- Durability of Seals and Latches: The latches and seals are the most frequently stressed components. High-quality cases use robust, metal latches and replaceable gaskets to ensure the case remains sealed over its long service life.