1 Electromagnetic Interference—A Growing Challenge to Equipment Performance and Reliability

1.1 An Invisible Threat in High-Tech Work Environments

Electromagnetic interference (EMI) is omnipresent across modern industrial, medical, and communications settings. From high-frequency radio waves to power line emissions, these signals constantly disrupt sensitive electronic equipment. Unlike surface-level glitches, EMI can penetrate deep into circuits, sensors, and control systems, causing enduring degradation in performance, and accelerating component wear.

1.2 Precision-Critical Industries Face Heightened Risks

In fields like medical imaging, surgical robotics, and automated manufacturing, even minor data corruption or control inaccuracies can cause cascading failures. For example, a misinterpreted diagnostic signal or a timing lapse in robotic control due to EMI could lead to safety breaches, production halts, or even irreversible human impact. Equipment in these environments demands uncompromising electromagnetic protection.

1.3 The Urgent Need for Advanced Shielding Solutions

As technology continues to miniaturize and operational frequencies rise, traditional methods of EMI mitigation—such as basic enclosures or grounding—are no longer sufficient. Enterprises now require dedicated, engineered shielding components that can actively deflect, absorb, and neutralize electromagnetic interference while preserving the signal integrity and long-term operational efficiency of critical systems.

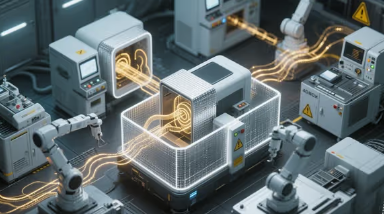

2 AD BOX Shielding Cover—A High-Performance Shield Against Electromagnetic Disruption

2.1 Advanced Materials and Precision Structure for Optimal EMI Blocking

The AD BOX Shielding Cover is built using highly conductive alloys and multi-layered shielding fabrics, engineered to reflect and absorb electromagnetic waves across a wide frequency spectrum. Its optimized geometry and fit ensure complete coverage of susceptible zones, preventing EMI from infiltrating core processing units, communication modules, and signal lines.

2.2 Real-World Protection in High-EMI Environments

Whether in proximity to powerful motors, wireless transmitters, or medical imaging machines, devices shielded by the AD BOX maintain functional integrity. Unlike generic shields that offer partial protection, AD BOX enables equipment to operate continuously and precisely—even within intense EMI fields—by stabilizing internal voltage conditions and preventing false triggering or feedback delay.

2.3 Seamless Integration for High-Duty Applications

Designed with flexibility and compatibility in mind, the AD BOX Shielding Cover can be easily adapted to various devices, from compact PCBs in handheld equipment to large-scale industrial cabinets. Its non-intrusive design ensures that the installation process doesn’t compromise device form factor or accessibility, while providing uninterrupted protection during both operation and maintenance cycles.

3 From Signal Integrity to Equipment Longevity—The Broader Benefits of AD BOX Shielding

3.1 Enhancing Internal Signal Clarity and Operational Accuracy

Beyond blocking external noise, AD BOX also prevents internal signal interference—common in densely packed electronics—by stabilizing signal transmission paths. This is crucial for equipment requiring millisecond-level response or data consistency, such as diagnostic instruments, CNC machinery, and autonomous control units. The result fewer input/output errors, improved real-time communication, and consistent task execution.

3.2 Reducing Downtime and Maintenance Through Prolonged Component Life

Exposure to sustained EMI can lead to microprocessor instability, capacitor stress, and circuit overheating—culminating in frequent failures and rising maintenance costs. AD BOX minimizes these risks by maintaining a stable thermal and electrical environment, thereby extending the operational life of vital components and reducing the frequency of system resets, part replacements, or unscheduled downtime.

3.3 Strengthening Safety Standards in Mission-Critical Applications

In environments where human life, large-scale operations, or sensitive data are at stake, equipment reliability is non-negotiable. AD BOX contributes directly to system safety by preventing misoperations, communication lags, or power anomalies induced by EMI. Its adoption is especially relevant in sectors like aerospace, healthcare, and critical infrastructure, where even a minor malfunction can lead to significant consequences.