Metal mold design and fabrication are critical processes in the manufacturing industry, enabling the production of precise and durable parts. Achieving a balance between cost and quality is essential for competitiveness in the market.

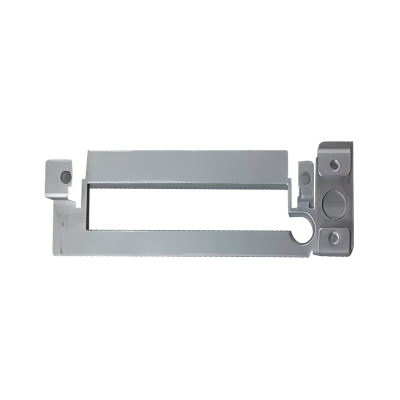

Metal mold design and fabrication involve creating molds from metal materials to shape molten metal into desired forms. This process requires expertise in material selection, design principles, and fabrication techniques.

Implementing cost-effective strategies in metal mold production can lead to significant savings, improved efficiency, and enhanced product quality, thereby providing a competitive edge.

Designing molds with manufacturability in mind can reduce complexity and cost. Simplifying features and minimizing the number of parts can lead to more efficient production.

Choosing appropriate materials can impact both cost and quality. Materials should be selected based on their properties, availability, and cost-effectiveness.

Advanced simulation tools can predict potential issues in the design phase, allowing for adjustments before fabrication begins, thus saving time and resources.

Applying lean manufacturing principles can eliminate waste, reduce costs, and improve efficiency in the fabrication process.

Integrating automation into the fabrication process can increase precision, reduce labor costs, and improve production speed.

Deciding between outsourcing fabrication or keeping it in-house depends on factors like cost, control, and capacity.

Implementing stringent quality control measures ensures that molds meet required specifications and standards, reducing the likelihood of defects and rework.

Maintaining and calibrating equipment ensures consistent performance and prevents costly breakdowns.

Investing in training and skill development enhances workforce competency, leading to improved productivity and quality.

By redesigning molds to use less material without compromising quality, a company reduced material costs by 15%.

Applying lean principles led to a 20% increase in production efficiency and a 10% reduction in lead time.

Integrating automation reduced labor costs by 25% and improved product consistency.

Implementing cost-effective strategies in metal mold design and fabrication involves optimizing design, selecting appropriate materials, utilizing advanced tools, and ensuring quality assurance.

Advancements in technology, such as additive manufacturing and artificial intelligence, are expected to further enhance cost-effectiveness and quality in metal mold production.

Cost-effective design reduces production expenses, minimizes waste, and improves overall efficiency, leading to increased profitability.

Automation increases production speed, reduces labor costs, and enhances precision, leading to cost savings.

Materials like aluminum and certain alloys offer a balance between cost, durability, and ease of fabrication, making them ideal for cost-effective mold production.