In the world of precision metal forming, deep drawing parts are fundamental components across countless industries. This process transforms sheet metal into complex, seamless shapes, offering unparalleled strength and consistency. For businesses seeking reliable manufacturing partners, understanding the nuances of deep drawing is crucial. This guide delves into the process, its advantages, and key considerations for your projects, highlighting the expertise required for high-quality production.

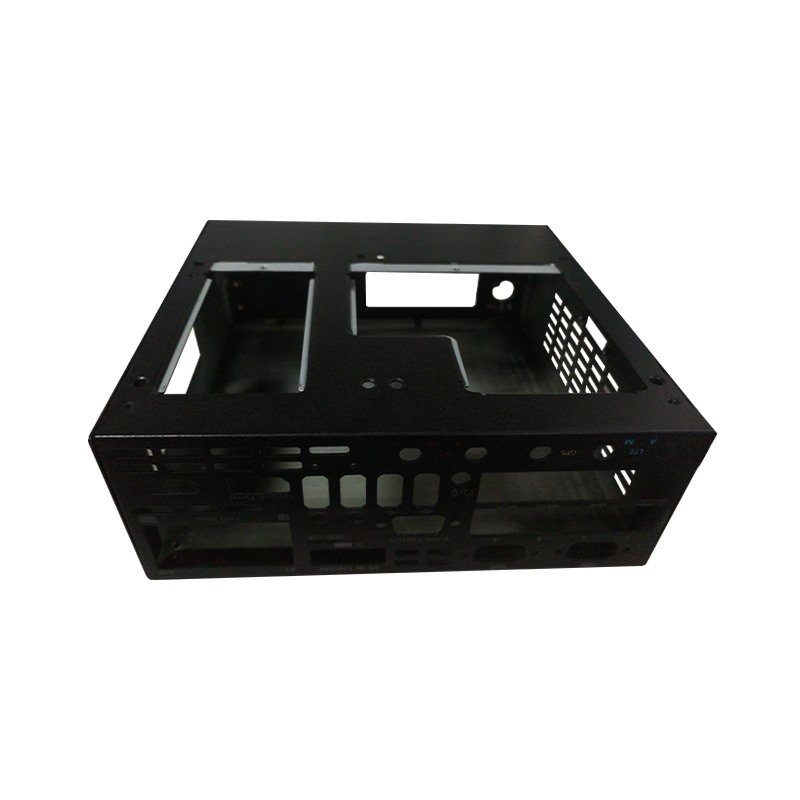

Deep drawing is a specialized sheet metal forming process where a metal blank is radially drawn into a forming die by the mechanical action of a punch. It is ideal for creating hollow, axisymmetric, or box-shaped components with depths that exceed their diameters. The applications are vast, spanning from critical automotive fuel injectors to delicate medical device casings and consumer electronics enclosures.

Successful deep drawing begins with design. Adhering to proven guidelines is essential for manufacturability, cost-control, and part performance.

| Good Practice | Challenging Practice |

| Using a corner radius equal to 4-6 times the material thickness. | Employing sharp, near-zero radii on corners. |

| Specifying a draft angle of 1-2 degrees per side. | Designing vertical, zero-draft sidewalls. |

| Maintaining uniform wall thickness throughout the part. | Designing significant variations in wall thickness. |

Stainless steel is a popular choice for deep drawing parts requiring corrosion resistance, strength, and a hygienic surface. However, its work-hardening rate presents unique challenges.

| Austenitic (e.g., 304) | Ferritic (e.g., 430) |

| Excellent ductility and formability. | Good formability but less ductile than austenitic grades. |

| High work-hardening rate, may require annealing. | Lower work-hardening rate. |

| Superior corrosion resistance. | Good corrosion resistance, but less than austenitic. |

Choosing the right partner for aluminum components is critical. Aluminum is lightweight and conductive but can be prone to tearing and surface scratches.

Since its founding in 2012, Suzhou Heaten has developed rich experience as a precision part manufacturer, working extensively with aluminum and other non-ferrous metals. Our portfolio, serving the automotive and consumer electronics sectors, demonstrates our capability in handling the specific challenges of the aluminum deep drawing parts manufacturer process.

Off-the-shelf solutions rarely meet specialized engineering needs. custom deep drawing metal components offer tailored solutions for unique applications.

| Custom Components | Standard Components |

| Tailored to exact application specifications. | Designed for general, broad-use cases. |

| Higher initial tooling investment. | Lower or no tooling cost. |

| Perfect fit and function for the assembly. | May require design compromises. |

Before committing to full-scale production, a prototype deep drawing parts service is an invaluable step to validate design, fit, and function.

At Suzhou Heaten, we leverage our precision metal mold design expertise and 30 sets of stamping equipment to offer efficient prototype deep drawing parts service. This allows our clients to iterate and perfect their designs with confidence before moving to high-volume manufacturing.

Founded in 2012, Suzhou Heaten is a professional metal mold design & fabrication supplier and precision part manufacturer. Our focus on deep drawing is supported by comprehensive in-house capabilities.

The most common materials include various grades of stainless steel (for corrosion resistance), aluminum (for lightweight and conductivity), copper (for electrical applications), and low-carbon steels (for general purpose, cost-effective parts). The choice depends on the application's requirements for strength, corrosion resistance, formability, and cost.

Parts suitable for deep drawing are typically hollow, cup-like, or box-shaped with a depth greater than their diameter or minimum cross-section. They should be designed with generous radii, uniform wall thickness, and sufficient draft angles. Consulting with a manufacturing engineer early in the design phase is the best way to determine suitability.

Stamping is a broader term that encompasses various processes like blanking, piercing, and bending to create flat or moderately formed parts. Deep drawing is a specific type of stamping focused on pulling a sheet metal blank into a die to create significant depth, resulting in three-dimensional, hollow shapes.

The mold design directly controls the material flow, preventing defects like tearing, wrinkling, and thinning. A well-designed mold with the correct punch and die radii, clearances, and surface finish is essential for producing high-quality, consistent deep drawing parts and maximizing tool life.

Yes, secondary operations are very common. These can include trimming, piercing, tapping, threading, welding, deburring, and various surface finishes such as plating, painting, or powder coating. An integrated manufacturer like Heaten can manage these value-added processes seamlessly.